Software-based emissions monitoring is gaining serious attention across regulated industries. Facilities are under pressure to reduce operating costs, maintain compliance, and improve data usability, all while adapting to evolving EPA expectations.

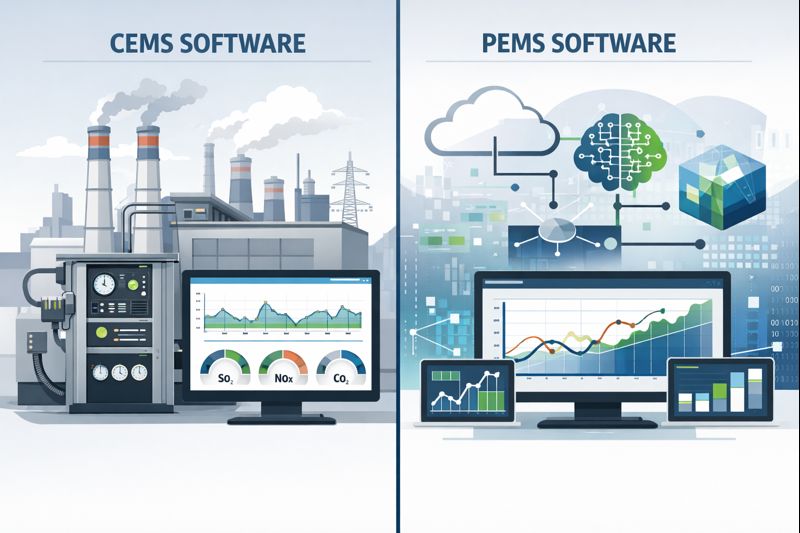

In this shift, one area of confusion persists: the difference between CEMS software and PEMS software. While both play roles in emissions compliance, they serve very different purposes and come with distinct operational implications. In this guide, we explain how each system works, where the differences truly matter, and how facilities can make compliance-driven decisions.

What Is CEMS Software?

CEMS software functions as the digital backbone of traditional Continuous Emissions Monitoring Systems. Its primary role is to support physical analyzers installed at stacks or ducts. The software collects data from analyzers, manages calibrations, performs data validation, and generates regulatory reports.

CEMS software depends entirely on hardware performance. Gas analyzers, probes, shelters, sample conditioning systems, and calibration equipment provide the raw emissions measurements. The software ensures these measurements are logged correctly, flagged when quality assurance thresholds are missed, and formatted for compliance reporting. Without functioning hardware, CEMS software has no emissions data to manage.

What Is PEMS Software?

PEMS software operates on a fundamentally different principle. Instead of managing direct measurements, Predictive Emissions Monitoring Systems use statistical models to predict emissions based on process operating data. Inputs may include fuel flow, temperatures, pressures, combustion parameters, and other control system variables.

PEMS software functions without physical emissions analyzers. It relies on validated models developed using historical emissions data and maintained through ongoing quality assurance procedures. Under EPA-approved frameworks, PEMS must meet strict validation, RATA testing, and performance monitoring requirements to remain compliant.

Key Difference #1 – Measurement vs Prediction

The most critical distinction is how emissions data is generated. CEMS software supports direct measurement. Analyzers physically sample exhaust gases and measure pollutant concentrations in real time. Accuracy depends on hardware condition, calibration quality, and environmental stability.

PEMS software relies on predictive modeling. Emissions are calculated using mathematical relationships between emissions and operating parameters. Accuracy is achieved through model development, validation, and continuous performance tracking. Both systems can meet regulatory standards, but the path to accuracy differs significantly.

Key Difference #2 – Installation and Infrastructure

CEMS software requires extensive physical infrastructure. Stack access, shelters, power, heated lines, sample conditioning, and analyzer cabinets are all necessary. Installation often involves outages, structural modifications, and long commissioning timelines.

PEMS software has a minimal physical footprint. It integrates with existing plant control systems, databases, and networks. This reduces installation time, eliminates stack modifications, and minimizes disruption to operations. Facilities often find this difference especially important when retrofitting older units or expanding monitoring across multiple assets.

Key Difference #3 – Ongoing Maintenance and QA

With CEMS software, quality assurance revolves around hardware. Daily calibration checks, quarterly audits, component replacements, and analyzer repairs are ongoing requirements. These tasks demand skilled technicians and regular downtime.

PEMS software shifts QA toward data quality and model performance. Maintenance focuses on validating inputs, monitoring prediction accuracy, and updating models when process conditions change. Staffing needs are typically lower, but technical expertise in data validation and regulatory QA remains essential.

Key Difference #4 – Cost Over the System Lifecycle

CEMS systems carry high lifecycle costs. Capital expenses include analyzers, shelters, installation, and infrastructure. Operating costs accumulate through maintenance labor, spare parts, consumables, calibration gases, and system downtime.

PEMS systems generally require lower upfront investment and reduced operating expenses. There are no analyzers to replace or shelters to maintain. Over time, especially for multi-unit facilities, the total cost of ownership is often significantly lower. However, cost should never override regulatory suitability.

Key Difference #5 – Flexibility and Future Readiness

CEMS software is limited by physical constraints. Process changes may require analyzer relocation, hardware upgrades, or new installations. Expansion across units can be costly and time-consuming.

PEMS software adapts more easily to change. Models can be updated to reflect operational shifts, and deployments can scale across units or facilities without physical barriers. As EPA reporting and digital compliance expectations evolve, software-centric systems offer greater long-term flexibility.

Which Option Is Right for Your Facility?

CEMS software remains the correct choice where regulations require direct measurement or where process variability prevents reliable modeling. Facilities with existing infrastructure and staffing may also prefer analyzer-based systems.

PEMS software is often better suited for facilities seeking lower lifecycle costs, reduced maintenance burden, and scalable compliance solutions, provided regulatory acceptance is confirmed. The decision should always be based on permit requirements, operational realities, and long-term compliance strategy.

Summary

CEMS software and PEMS software are not competing technologies. They are different tools designed for different compliance paths. Understanding how each system works, what it requires, and where it excels allows facilities to choose solutions that meet both regulatory obligations and operational goals. Contact us at CMC Solutions for more information. Let’s discuss which system is right for your operations.

Frequently Asked Questions – FAQs.

What is the difference between CEMS and PEMS?

CEMS directly measure emissions using analyzers, while PEMS predict emissions using validated statistical models based on operating data.

What is the difference between CEMS and CAAQMS?

CEMS monitors emissions from a specific source, while CAAQMS monitors ambient air quality in the surrounding environment.

What is the CEMS method?

The CEMS method involves continuous, direct measurement of pollutants using installed analyzers and regulated QA procedures.

How much does a continuous emissions monitoring system cost?

Costs vary but often include high capital investment and ongoing operating expenses that can exceed several hundred thousand dollars over the system’s lifetime.